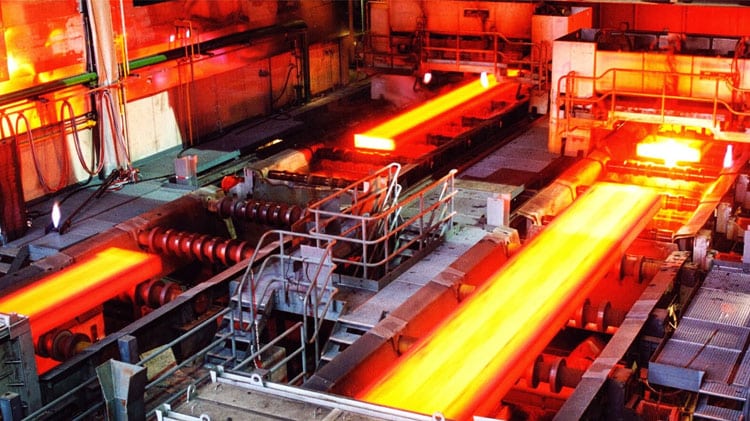

The domestic steel re-bar prices are feared to cross Rs. 150,000 per ton on a massive surge in global scrap rates, which have gone up from $350 per ton in October to $455 per ton, and a recent 10 percent increase in power tariffs for the energy-intensive steel industry.

Stakeholders in the steel industry say the higher steel prices could jeopardize the government’s plans to encourage the construction sector, in general, and housing, in particular, unless it takes immediate measures to help the steelmakers bring down their prices by reducing their electricity bills and decreasing turnover/minimum tax.

The industry needs the government’s assistance on a war-footing to survive. The steel industry was already struggling to cope with the rising international scrap prices when the government raised the power tariffs by 10 percent.

“Global scrap prices are set to spike with growth in demand for ferrous scrap in China to 12 million tons a year,” Secretary-General PALSP, Wajid Bukhari, said. Further adding, “The increase of Rs. 4 per unit in the electricity tariff for Pakistan’s nascent steel industry will prove to be the proverbial last straw on its back and detrimental to the government plans for affordable housing for the low-middle-income people.”

Members of the Pakistan Association of Large Steel Producers (PALSP) are one of the major consumers of K-Electric. PALSP has lodged a severe protest over the recent increase in tariff through SRO No. 192 dated 12th February 2021.

This increase is creating a crisis-like situation for the struggling steel sector of Pakistan. Through this SRO, Rs. 1.95/kWh has increased in variable charges and Rs. 40/kW per month increase in fixed charges. Fixed charges should reduce instead of increasing.

If a consumer is using his connection and paying variable charges, then he should be levied only when the variable charges are under a certain threshold.

In Pakistan, all cost of the distribution system (grid, cable, substation, transformer, etc.) has to be borne by the consumer, then why should the customer pay heavy fixed charges for electricity connection.

The Association is of view that the tariff change and the regime should be reconsidered and properly aligned. In Bangladesh, (DPDC) fixed charges are only 70.92 US cents for B4 customers. Whereas it is 250 US cents (after a recent increase) in Pakistan, meaning the tariffs are over 350 percent of our regional competitors.

Imports of Iron and Steel Scrap Down by 13.5 percent

According to the Pakistan Bureau of Statistics (PBS), the imports of iron and steel scrap into Pakistan rose by 13.5 percent in 2020 compared to the previous year, with annual iron and steel scrap imports rising to 4.57 million tons from 4.02 million tons.

The industry has long been pleading for a cut in the turnover tax of 1.5 percent on the steel industry to 0.25 percent to provide it a breathing space.

“We’ve been pursuing the matter for long, and in principle, there has been a broad consensus that this is an unfair tax on the documented sector, which is already bleeding. The authorities say the issue will be addressed in the upcoming budget, which is not justifiable because it will be too late for the industry by then,” PALSP argues.

The government has already slashed, through an ordinance, the minimum tax for dealers and sub-dealers of sugar, cement, and edible oil to 0.25 percent, whose names are on the active taxpayers’ list issued under the provisions of the Sales Tax Act, 1990 and the Income Tax Ordinance, 2001.

Now, as a special favor, the wholesalers and retailers of fast-moving consumer goods, fertilizer, sugar, cement, and edible oil have also been included in this category.

“The steel industry operates on very thin margins. Thus, the existing rate of minimum tax is not only a burden on the cash flow of manufacturers but will also discourage future investment in the industry. It also discourages documentation of steel transactions. The FBR also makes only a little revenue from it because the downstream sector of the long steel industry remains undocumented,” concludes Bukhari.

Another major issue facing the documented steel sector is the tariff anomalies, which are creating unfair competition in this sector and making the documented sector bleed money.

For example, the abuse of some concessions given to erstwhile FATA/PATA is resulting in a loss of Rs. 10-15 billion annually to the national exchequer and killing the entire steel sector.

Similarly, lacunas in the customs rules allow large-scale tax evasion through misdeclaration of brand new steel as re-rollable scrap. “All factors have created a crisis for the steel sector,” Bukhari says.

“In the budget 2019-20 the FBR abolished special regime for collection GST from the steel sector to the normal ad-veloram, opening the floodgates of tax evasion and giving tax evaders advantage over the documented sector. Further, in order to make the Naya Housing Project a success, the government should abolish 17 per cent sales tax on this project,” noted Hussain Agha, Chairman Media PALSP.

He added, “Our ultimate focus is to support Pakistan and become the ignition and driving force for Naya Pakistan Housing, however, with abnormally highest energy tariff prices regionally and tax rates for steel products double to other nations, it will become a struggle. We must be forward-looking and aim to seek a win-win solution otherwise we fear that prices will spiral out of control.”

Pakistan’s Steel Industry

The products of Pakistan’s steel industry comprise of three types; flat, round, and long. Flat steel may be understood as a raw material for cars, round steel will be the one used in pipes, and long steel – which comprises approximately 60 percent of the total steel production in the local industry – is what is used in construction. From this one sentence, one could imagine the length and breadth of the related industries and economic segments dependent on and associated with the steel sector.

It is not just about the economics of the steel sector either. The range of stakeholders directly or indirectly involved with this part of Pakistan’s manufacturing industry is equally diverse.

The steel sector of Pakistan comprises some 300 companies that manufacture over six million tons of steel annually. In the last two to three years, some companies have declared losses; some are selling below the construction costs, just to avoid a complete shutdown, while some brought down their shutters altogether.

Those companies that are still operational employ north of 100,000 people and contribute approximately Rs. 150 billion to the national exchequer. According to the Pakistan Association of Large Steel Producers (PALSP), the local production of steel also accounts for import substitution of $1.2 billion.